Best Practices in Manual Handling: Tips for Aussie Businesses

Why Aussie Businesses Need Manual Handling Training

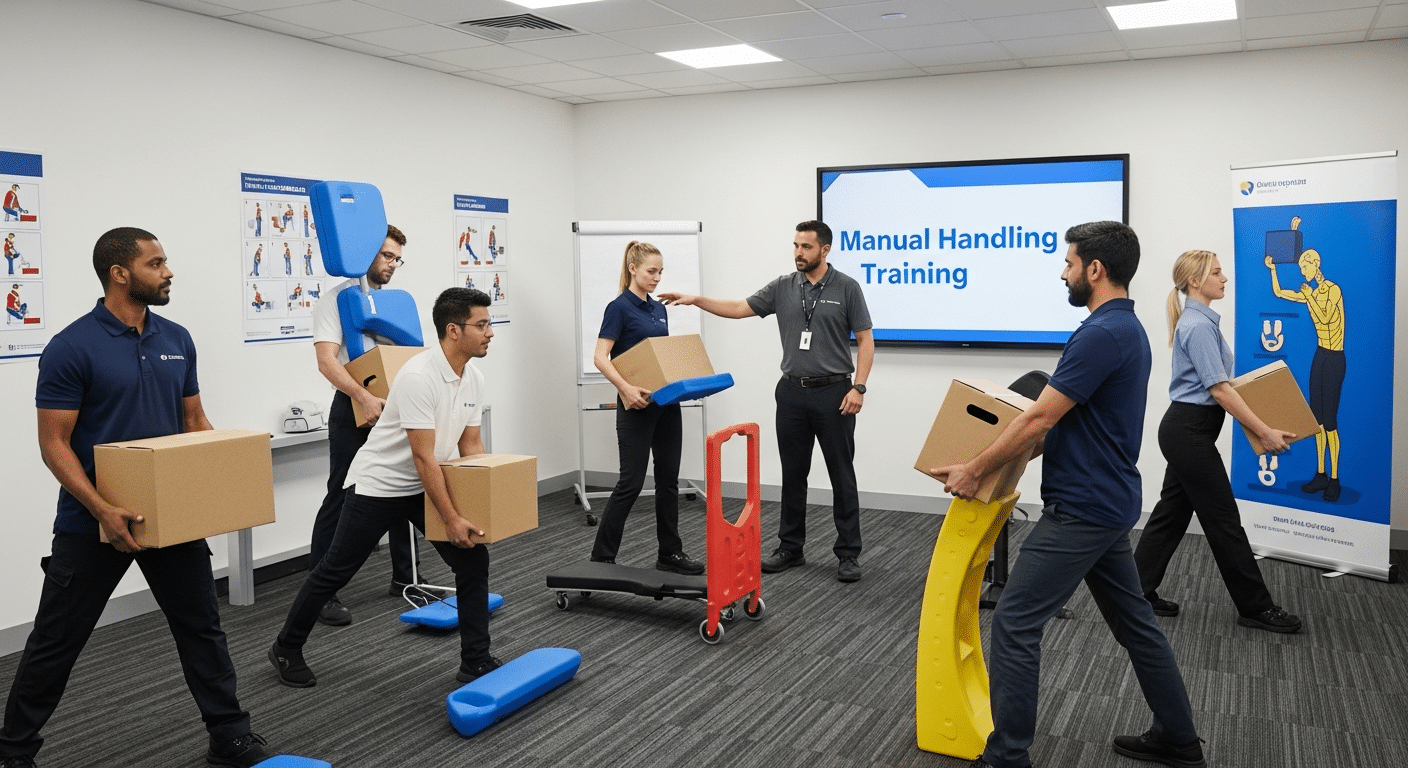

Many people have to lift boxes in stores or move heavy equipment in warehouses every day. But if you don’t know how to properly handle things by hand, you could get hurt badly, like with sprains, strains, and back problems. These injuries can hurt workers and also cost businesses a lot of money in workers’ compensation claims and lower productivity.

According to Work Health and Safety (WHS) laws in Australia, businesses must make sure that their workers know how to safely handle things by hand. Businesses show they care about their workers’ health and safety by putting manual handling training at the top of their list of things to do. This lowers the risk of injury.

What is Manual Handling?

Any action that involves lifting, carrying, pushing, pulling, or moving an object by hand or body force is called “manual handling.” In a work setting, this includes things like lifting boxes or tools.

- Carrying goods or stock

- Pushing or pulling carts or trolleys

- Moving heavy things around

- While handling materials, you have to reach, bend, or twist.

In many industries, such as retail, healthcare, and construction, manual handling is an important part of many daily tasks. To make work places safer, you need to know what it covers and what risks it poses.

Common Risks and Injuries from Manual Handling

In Australia, one of the most common causes of workplace accidents is injuries from manual handling. The most common injuries that happen when people don’t handle things properly are:

- Musculoskeletal disorders (MSDs): When the body moves too much or in an awkward way, it can get hurt, like with strains, sprains, and chronic back pain.

- Sprains and strains: Usually happen when you lift too much weight, have bad posture, or do the same thing over and over again.

- Back injuries: Lifting heavy things the wrong way or twisting while lifting can hurt your back badly.

- Joint damage: Doing the same thing over and over again or having bad posture can cause inflammation and damage to your joints over time.

According to Safe Work Australia, more than half of all workers’ compensation claims are for musculoskeletal injuries. This shows how important it is to handle things safely.

The Law in Australia Says You Must Have Manual Handling Training

Australian Work Health and Safety (WHS) laws say that employers must give training to workers who do manual handling tasks. These laws try to lower risks by making sure that businesses check for hazards, teach workers how to work safely, and give them the right tools.

Employers must:

- Do risk assessments to find dangerous manual handling tasks

- Put in place controls to lower risks, like adding mechanical aids or changing the way tasks are done.

- Teach people how to lift things safely and how to handle things correctly.

- Check and update safety procedures on a regular basis

If a business doesn’t follow these rules, it could face big fines, penalties, and more liability in case of accidents.

Top 7 Questions About Manual Handling Training

What does Australian WHS law mean by “manual handling”?

Lifting, carrying, pushing, pulling, or moving things with your body are all examples of manual handling. It applies to a lot of things that people do at work, like moving boxes, moving equipment, or pulling carts.

What are the most common risks and injuries that come from bad manual handling at work?

Musculoskeletal disorders (MSDs), back injuries, strains, and joint damage can all happen if you don’t handle things properly. Some risks are lifting heavy things the wrong way, doing the same thing over and over, being in an uncomfortable position, and not getting enough rest.

What are the legal responsibilities of businesses and employers when it comes to manual handling?

Employers must make sure that their workers are safe by checking for risks when they handle things by hand, teaching them how to do it safely, and giving them the tools they need. They also need to put in place safety measures to reduce injuries and make sure they follow WHS laws.

How should a company look at and deal with the risks that come with manual handling tasks?

Companies should find manual handling tasks, look at the risks (like weight, posture, and frequency), and put controls in place to lower those risks. These could be changing the way a task is done, adding mechanical aids, or giving the right training.

What are the right ways and techniques for “safe lifting and handling”?

When lifting, you should bend your knees (not your back), keep the load close to your body, use both hands, and avoid twisting your body. If you can, use mechanical aids or ask for help to make things easier on yourself.

When should you use mechanical aids or team lifting instead of doing it by hand?

When moving heavy or awkward things, you should use mechanical aids like trolleys or hoists. When a load is too heavy or big for one person to lift safely, they need to work together to lift it. Both methods help workers feel less physical stress.

What kind of training and workplace design should companies use to make sure that manual handling is safe?

Companies should teach their employees how to do manual handling correctly, how to assess risks, and how to use mechanical aids. It is also important to design workplaces ergonomically to lower the risk of injury. For example, lifting tasks should be done at a safe height and weight.

Important Parts of Good Manual Handling Training

The following are the most important parts of good manual handling training:

- Finding and evaluating risks: Training workers to spot tasks that could be dangerous for their hands.

- Safe lifting techniques: showing the right way to lift things without putting too much strain on your body, such as bending your knees, keeping your spine straight, and using mechanical aids. Training employees on when and how to use trolleys, hoists, and other lifting tools to lower the risk of manual handling.

- Posture and body mechanics: Making sure to lift, push, or pull in the right way to avoid getting hurt.

- Ongoing training and refreshers: Giving regular updates on training and encouraging people to always be aware of how to safely handle things by hand.

How to Set Up a Manual Handling Training Programme at Work

- To start a manual handling training programme:

Choose a course or trainer who is certified: Pick a trainer who knows a lot about WHS rules and how to safely handle things. - Set up training sessions:

Hold regular training sessions and make sure that all staff members who do manual handling go to them. - Track completion:

Keep track of employee training to make sure it is done and to look over it later. - Encourage a culture of safety:

Make sure that manual handling safety is a top priority at all levels of the business by encouraging people to talk about it all the time.

Training for manual handling is not only required by law, but it is also an important part of making the workplace safe and productive. Businesses can greatly lower the risk of injuries and improve employee health by teaching workers how to handle things correctly, giving them the right tools, and looking at the risks at work. Put safety first when it comes to manual handling in your business today to keep your employees safe and follow Australian WHS rules.